In today’s golf apparel market, brands need more than a logo to stand out. That’s why the Benefits of OEM & ODM Golf Cap Manufacturing for Brands matter. Working with professional factories allows companies to make high-quality caps that are stylish, durable, and affordable.

OEM and ODM models give brands flexibility to grow. From lower costs and faster production to custom designs and eco-friendly options, they provide real advantages that help brands succeed both on and off the course.

OEM vs ODM (what they mean & when each benefits a brand)

When it comes to golf cap manufacturing, two terms come up often: OEM and ODM. Both are proven ways for brands to get high-quality headwear, but they serve different needs.

OEM: Full Control for Unique Designs

With OEM (Original Equipment Manufacturing), your brand owns the design. The factory simply brings it to life based on your exact specs.

Maximum control over fit, feel, and style

Protects your intellectual property

Ideal for brands building a signature cap line

ODM: Speed and Lower R&D

With ODM (Original Design Manufacturing), you start with pre-engineered cap designs from the factory. You add your branding or adjust details.

Faster path to market—no need to design from scratch

Lower upfront development costs

Perfect for seasonal launches or event merch

ROI & Speed-to-Market

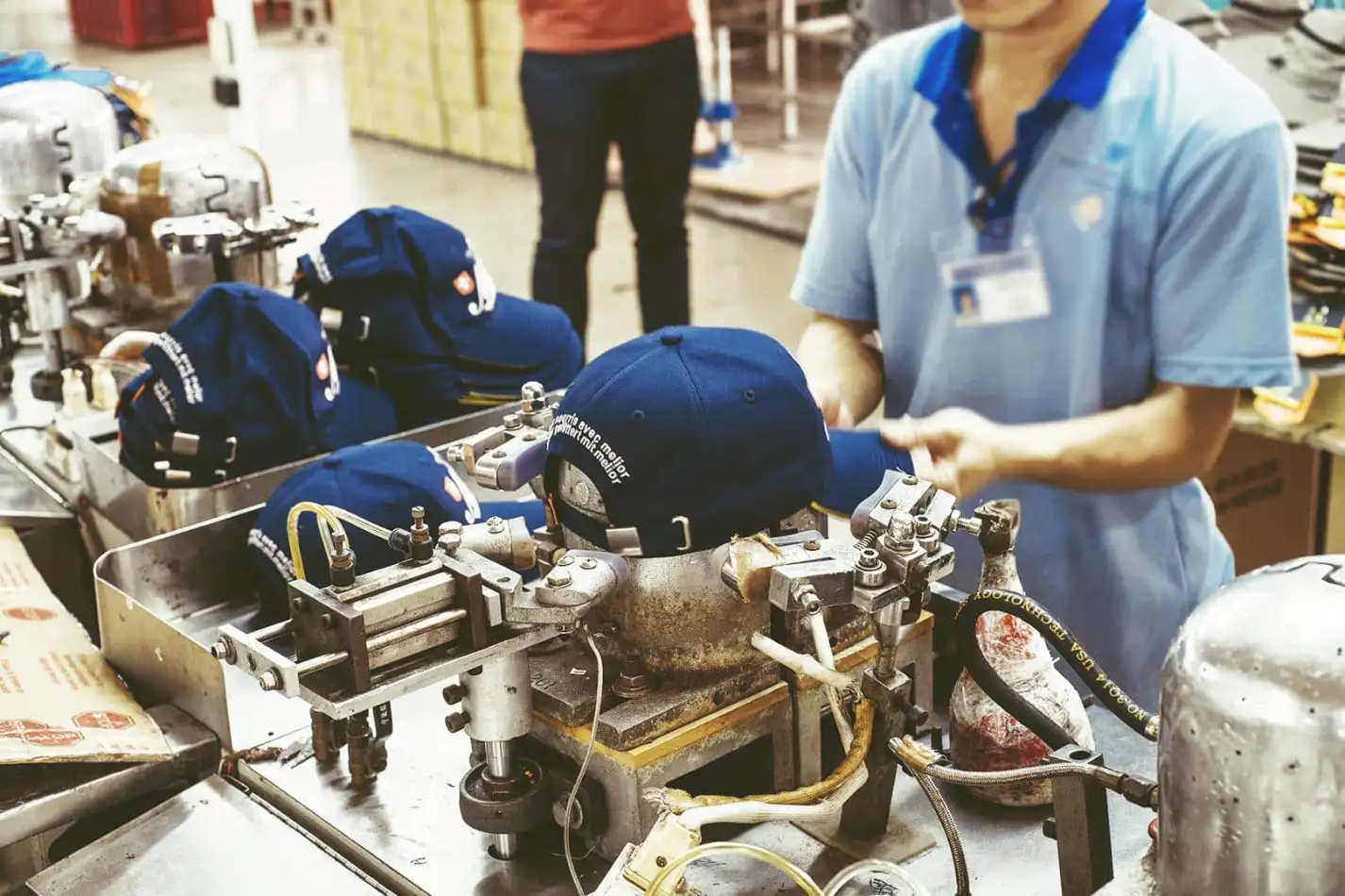

One of the biggest benefits of OEM and ODM golf cap manufacturing is the impact on return on investment (ROI) and how fast you can launch products. Working with the right factory partner means predictable costs and faster results.

Lower Costs Through Scale

Factories that specialize in golf caps already have the tools, materials, and labor in place. By producing at scale, they can offer:

Lower unit costs compared to local customization

Predictable pricing across large orders

Savings on R&D and testing when using ODM models

Faster Sampling and Production

Speed matters in golf apparel, especially for seasonal lines and tournaments. ODM options, in particular, make it easier to move quickly:

Samples in days, not weeks

Shorter production cycles for bulk orders

Ability to meet event deadlines with less stress

Brand Differentiation & Performance

For golf brands, standing out often comes down to materials and design details. OEM and ODM manufacturing give you the tools to create caps that not only perform well on the course but also reflect your brand’s unique style.

Golf-Specific Materials

Modern golf caps aren’t just about looks—they’re built for performance. With the right partner, you can choose:

UPF fabrics for sun protection

Moisture-wicking liners to keep players dry

Laser perforations for ventilation

Recycled yarns for eco-conscious buyers

Custom Decoration Options

Design details make your caps recognizable and memorable. Factories that offer OEM & ODM services usually provide a wide range of decoration methods:

3D puff embroidery for bold logos

Woven or silicone patches for a modern finish

Heat transfer printing for crisp, lightweight graphics

By combining advanced fabrics with unique decoration, brands can deliver golf caps that balance style, comfort, and performance.

Quality, Compliance & Reliability

For any golf cap brand, consistency and trust matter as much as design. OEM and ODM manufacturing give you access to proven processes that help maintain reliable quality across every order.

Consistent Fit and Finish

Reputable factories use established patterns and strict quality checks to keep every cap on-brand. This means:

Uniform sizing and shape across bulk orders

Durable stitching and seams that hold up on the course

Professional finishes that meet retail expectations

Testing and Compliance Standards

Quality also depends on compliance. Leading OEM and ODM partners handle important tests so your brand avoids costly mistakes:

Colorfastness testing to prevent fading or bleeding

UV/UPF verification for protective performance claims

Packaging and labeling standards to meet retail or shipping rules

By outsourcing these checks, brands can reduce risks and focus more on marketing, sales, and customer experience.

IP Protection & Risk Control

Protecting your designs and brand identity is essential when working with manufacturing partners. Both OEM and ODM models come with ways to secure your intellectual property and reduce risks.

Clear Ownership and Agreements

When you choose OEM, you fully own the design and IP. With ODM, exclusivity terms should be defined clearly. Strong documentation helps safeguard your brand:

NDAs (non-disclosure agreements) to protect design ideas

Detailed tech packs that outline exact specs

Exclusivity agreements for ODM styles to avoid copycat issues

Reducing Risk Before Production

Pre-production steps are key to minimizing mistakes and protecting brand value. By working closely with the factory, you can ensure:

Sample approvals before bulk production

Quality checks at every stage

Reduced rework and cost from early problem detection

With the right partner, OEM and ODM golf cap manufacturing gives your brand both creative freedom and protection against costly risks.

Operational Advantages (MOQs, Lead Times, Logistics)

Managing costs and timelines is one of the biggest challenges for growing brands. OEM and ODM golf cap manufacturing makes this easier by offering flexibility in minimum order quantities (MOQs), clear lead times, and straightforward shipping terms.

Right-Sized MOQs

Factories often set MOQs to keep production efficient, but many now offer flexible options that help brands balance cost and inventory:

Small-batch orders for testing new styles or markets

Larger runs for lower per-unit cost and better margins

Ability to scale quickly once demand grows

Transparent Lead Times & Logistics

Planning ahead is simpler with partners that provide clear timelines and global shipping support:

Sampling in days and bulk orders within weeks

Flexible shipping terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight)

Predictable delivery schedules that keep launches on track

By aligning MOQs, lead times, and logistics with your strategy, OEM and ODM partnerships reduce supply chain stress while keeping your brand agile.

Sustainability & Brand Trust

Today’s golf players expect more than just style and comfort. They also want brands that care about the environment. OEM and ODM golf cap manufacturing helps your brand meet those expectations by building sustainability into the production process.

Eco-Friendly Materials and Practices

Factories now offer responsible options that align with modern brand values:

Recycled fabrics made from PET bottles or reclaimed fibers

Traceable sourcing for transparency in supply chains

Durable construction that extends product life and reduces waste

Building Brand Trust

Sustainability isn’t just about materials—it’s also about perception. When customers see that your caps are responsibly made, they connect deeper with your brand. This can lead to:

Stronger customer loyalty

Better brand reputation in competitive markets

More opportunities to appeal to eco-conscious golfers

By combining performance with sustainability, OEM and ODM partners help your brand earn trust while reducing its environmental footprint.

Conclusion

The Benefits of OEM & ODM Golf Cap Manufacturing for Brands are straightforward: they let companies scale production, cut costs, and launch distinctive, high-quality caps that build brand trust.

At Jointop, we specialize in OEM and ODM golf cap manufacturing and support brands of every size. With factories in China, Bangladesh, and Vietnam, we provide quick sampling, competitive pricing, and flexible MOQs to meet your exact needs.

Whether you’re building a signature golf cap collection, creating seasonal drops, or preparing promotional caps for events, our team is ready to help. Contact us today to start designing caps that bring your brand vision to life.

FAQs

What is the minimum order quantity (MOQ) for OEM and ODM golf caps?

MOQ varies by factory, but many start at around 100–300 pieces. Some suppliers allow smaller test runs, while larger orders reduce cost per unit.

Can OEM and ODM caps be customized for different head sizes?

Yes. Factories use adjustable closures like snapbacks, Velcro, and straps to fit a range of head sizes. OEM also allows exact sizing in the design stage.

How long does it usually take to get samples approved?

Samples are often ready within 5–7 days. ODM samples may be faster since the base design already exists, while OEM samples can take longer due to custom specs.

Are eco-friendly materials more expensive than standard fabrics?

They can cost slightly more, but many brands find the added value in sustainability and customer trust offsets the higher price. Some factories now offer cost-efficient recycled fabrics.

Do OEM and ODM manufacturers provide packaging services?

Yes. Most offer retail-ready packaging options, such as swing tags, printed boxes, or custom labels. This helps brands deliver a complete product directly to market.